About Us

METECH is a premier provider of condition monitoring services for rotating equipment. Our cutting-edge solutions empower businesses to optimize the performance, reliability, and lifespan of critical machinery. By employing advanced technologies and techniques, we monitor, analyze, and assess the health of rotating equipment, enabling proactive maintenance, minimizing unplanned downtime, and maximizing operational efficiency across diverse industries including oil & gas, power generation, manufacturing, mining, and more.

-

Proactive Maintenance Approach

Our services empower clients to transition from reactive to proactive maintenance strategies which helps to reduce operational risks and enhance overall productivity.

-

Customized Solutions

Recognizing the unique challenges of each industry and business, we provide customized condition monitoring solutions to address your specific operational requirements.

-

Our Mission

Empowering industries with reliable condition monitoring solutions for enhanced performance, reduced costs, and safe operations.

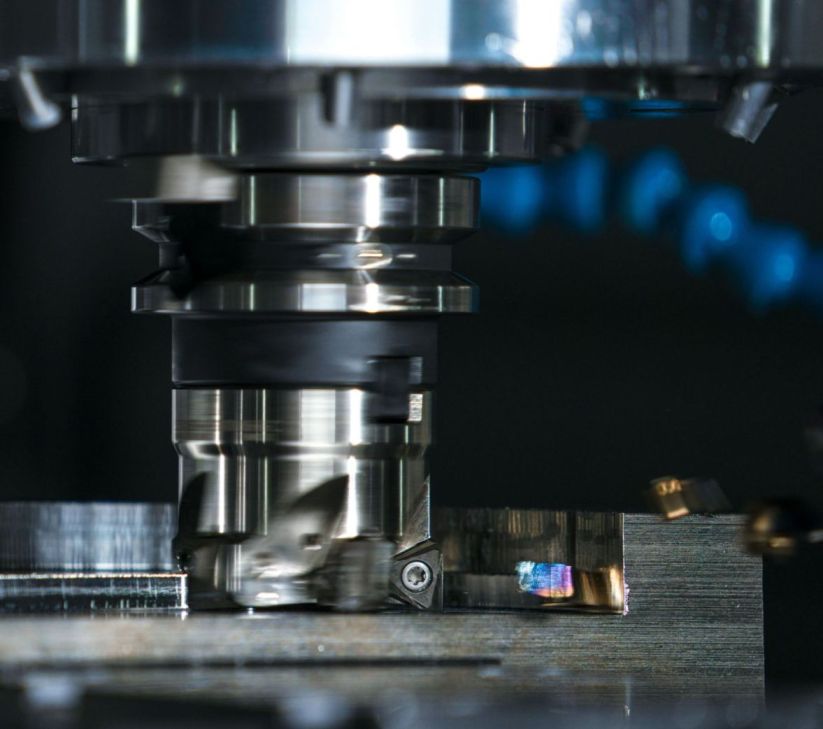

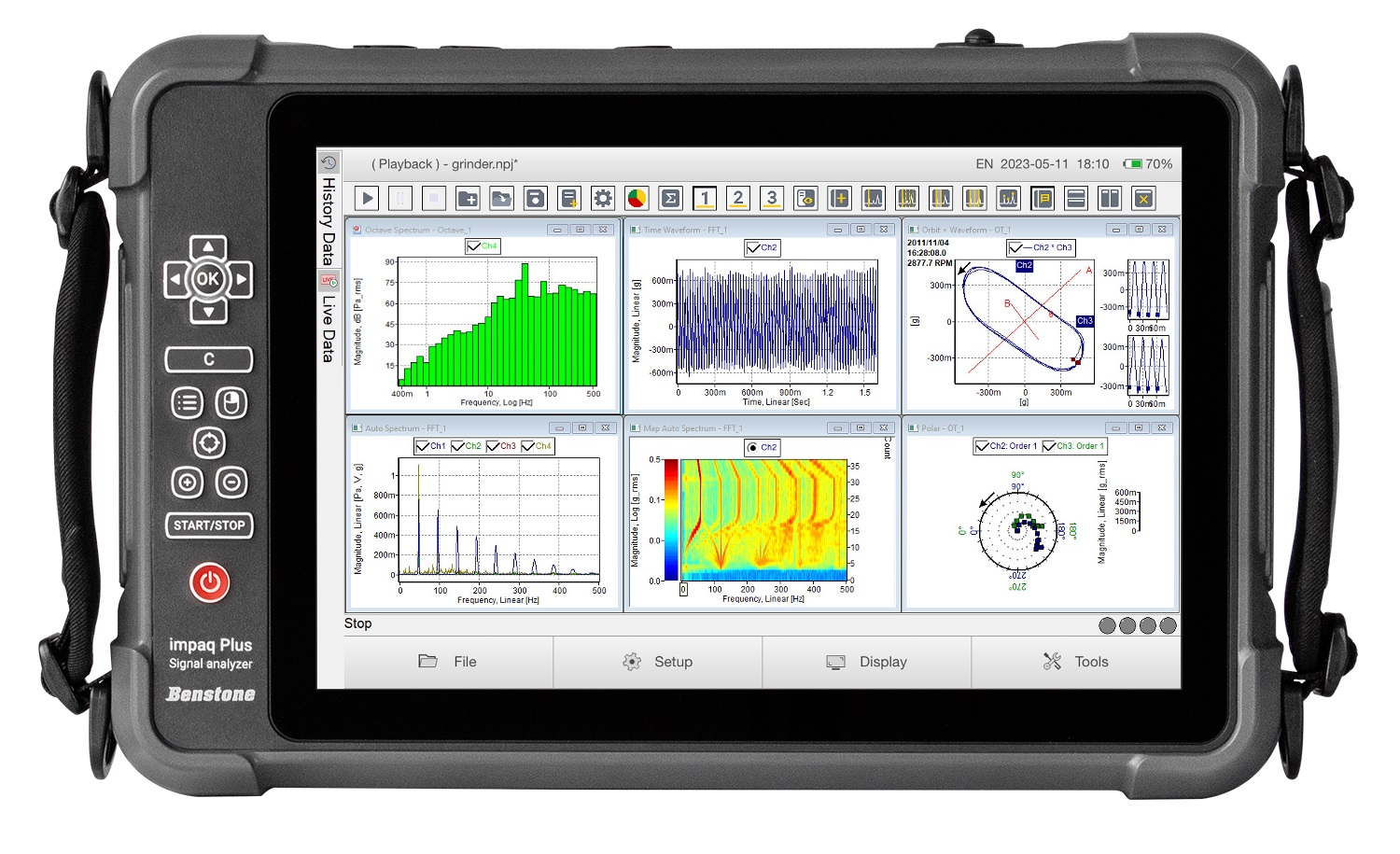

Vibration Analysis

Vibration analysis is a crucial preventative maintenance technique that allows us to identify potential equipment failures before they occur. By closely monitoring vibration levels and patterns, our experts can detect early warning signs like imbalance, misalignment, bearing defects, and mechanical looseness in rotating machinery. These insights are delivered through detailed reports, empowering our clients to take proactive measures and avoid costly breakdowns. Ultimately, our vibration analysis services help optimize equipment performance, reduce downtime, and extend the lifespan of critical assets.

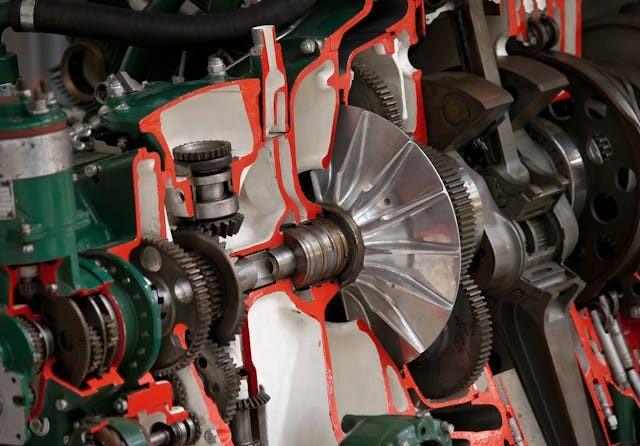

In-Situ Dynamic Balancing Services

Our in-situ dynamic balancing service offers a non-disruptive solution for maintaining optimal equipment performance. By conducting balancing procedures directly on-site, we eliminate the need for costly and time-consuming disassembly and removal. This streamlined approach minimizes operational downtime and ensures that your machinery operates smoothly and efficiently.

Thermography (Infrared Scanning)

Thermal imaging, or infrared scanning, is a powerful diagnostic tool that allows us to visualize heat distribution within electrical and mechanical equipment. By capturing thermal images of your machinery, our experts can pinpoint potential issues such as overheating motors, faulty wiring, and misaligned components. Early detection of these problems can prevent costly breakdowns, reduce energy consumption, and improve overall system reliability.

Oil Analysis

Oil analysis is a crucial tool for proactive maintenance. By analyzing oil samples, we can detect early signs of wear, contamination, and degradation in your machinery. This enables us to identify potential issues in critical components like bearings, gears, and hydraulic systems before they escalate into costly breakdowns.

Ultrasound Testing

Ultrasound testing is a non-destructive technique that utilizes high-frequency sound waves to inspect the internal components of rotating equipment. This method allows us to accurately identify potential problems, such as leaks, bearing failures, and cavitation, which can often go undetected by other inspection methods. By capturing and analyzing these high-frequency sound waves, we can pinpoint the exact location of the issue and take corrective action before it escalates into a major breakdown, saving time, money, and preventing potential safety hazards.

Laser Shaft Alignment

Proper shaft alignment is crucial for the efficient and reliable operation of rotating machinery. Misalignment can lead to increased vibration, excessive wear, and premature failure of critical components. Our laser alignment services utilize state-of-the-art technology to accurately measure and correct shaft misalignment, ensuring optimal performance and reducing downtime. By minimizing vibration, we help reduce energy consumption and extend the life of your equipment.

Pump Maintenance & Repair

We are committed to providing top-notch pump maintenance and repair services. Our team conducts regular inspections and maintenance to prevent breakdowns and optimize performance. Our skilled technicians utilize advanced diagnostic tools to quickly identify and resolve problems. We offer comprehensive repair services, including component replacement, to restore your pump to its optimal condition. Additionally, we perform system upgrades and modifications to improve efficiency, reliability, and energy consumption.

Motor Maintenance & Repair

Motor Maintenance and Repair services encompass a wide range of expertise, including electrical testing and diagnostics to pinpoint and rectify potential issues. Our specialized services include bearing replacement and alignment to ensure smooth operation and extend the motor's lifespan. Additionally, we offer rewinding and refurbishing services to restore worn-out motors to their original condition. To further enhance performance and reliability, we conduct vibration analysis and balancing procedures to identify and correct imbalances in the motor.

Preventative Maintenance Programs

We are implementing customizable maintenance schedules for tailor preventive measures to the specific needs of each piece of equipment. Our advanced performance monitoring and reporting tools provide real-time insights into equipment health, allowing us to make informed decisions and schedule maintenance proactively. To further enhance operational efficiency, we offer comprehensive training and support services to empower in-house maintenance teams. We ensure the seamless execution of preventive tasks, leading to optimal equipment performance and reliability.

Connect with Us

MeTech Experts are committed to your needs. Contact us today for timely support. Need tech help? We're just a call away. Got a tech question? MeTech Experts are here to help. Quick and reliable tech support.

Contact UsProducts

Contact

UAE Address

Business Bay

Dubai, UAE

Oman Address

Sohar

Al Falaj, Oman

Email Us

sales@metechexp.com

metechdxb2003@gmail.com

Call Us

00971585380388